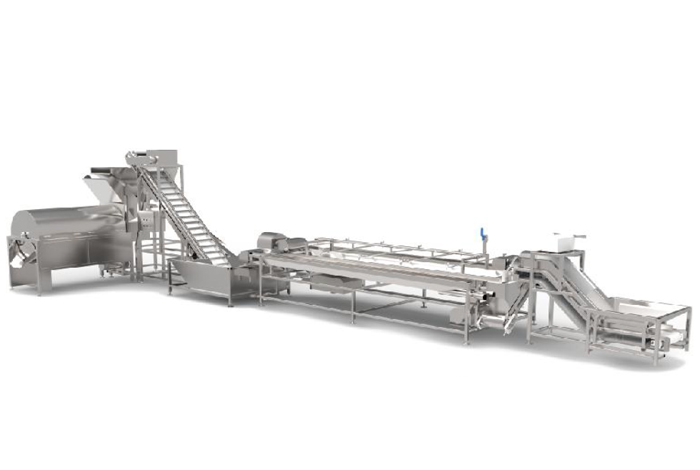

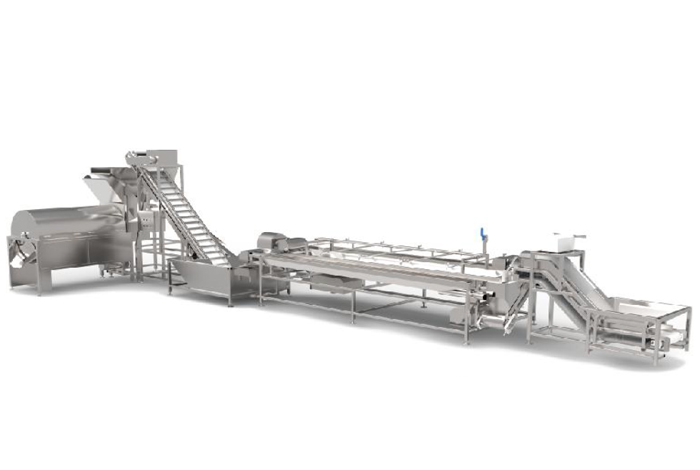

Sea Cucumber Processing Production Line

Zhongtong Food Machinery has been focusing on the manufacturing of various food machinery for 20 years, designing a complete set of assembly line process equipment from raw material pretreatment to final product packaging and storage for nearly a thousand domestic and foreign customers, providing users with complete solutions. In the past 20 years of development and progress, we have not only established a good brand image among domestic large and medium-sized customer groups, but also exported some of our equipment to multiple countries and regions such as Europe, Australia, Africa, Japan and South Korea, and Southeast Asia, receiving widespread praise and recognition from many users. We are rigorous, diligent, and strive for excellence. We humbly listen to feedback from every customer, continuously improve and perfect, and strive for customer satisfaction while also continuously improving the performance of our products. Our design team is also gaining increasingly rich design experience through long-term integration with users. Able to fully understand and grasp customer intentions and requirements.

Production line technology

-

Option 1: Loading elevator - Dirt removal table - Bubble cleaning machine - Vibration impurity removal machine (drum impurity removal machine) - Receiving vehicle - Flip steaming pot - Quick freezing machine

-

Option 2: Feeding elevator - Dirt removal table - Bubble cleaning machine - Elevator - Vibration impurity removal machine (drum impurity removal machine) - Elevator - Continuous pre boiling machine - Bubble cooling machine - Quick freezing machine

After years of production practice and combined with the mature experience of multiple professional sea cucumber processing enterprises in China, our company has continuously researched and innovated, and designed a more suitable assembly line for factory processing of sea cucumber, ensuring the quality of sea cucumber processing and greatly improving production efficiency.

Characteristics of the production line

-

The entire production line can set the production and processing speed according to customer requirements, and multiple cleaning stations can ensure that the products are cleaned thoroughly.

-

The manual circulation dirt removal machine ensures that the sea cucumber raw materials can automatically circulate after entering the dirt removal line. The unfinished raw materials are always on the equipment, and there will be no local shortage or stacking of materials. Each workstation has a flushing faucet, and the flushed dirt is collected along a dedicated sewage tank.

-

The automatic cooking machine can set the temperature range according to the processing technology through the automatic control system, and the temperature can be freely set from 70 to 100 degrees. The cooking time can be freely adjusted within a range of 3-30 minutes. Capable of meeting the requirements of various processing techniques.

中文

中文

中文

中文